![]()

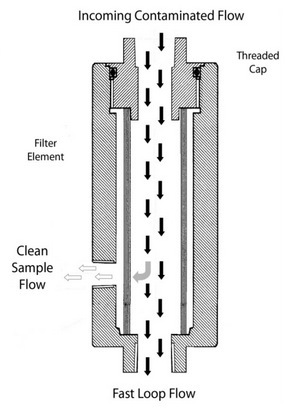

Our standard Fast Loop filters are constructed from 316L stainless steel. A straight through flow design continuously flushes the filter element carrying the contaminates back out to the process stream, thus maximizing the filter element life. The low flow sample stream pulled into the analyzer is filtered to ranges of 200 micron to 0.5 micron (depending on the filtration efficiency required). Traditional T-type by-pass filters are detailed under Analyzer Filters.

Our standard Fast Loop filters are constructed from 316L stainless steel. A straight through flow design continuously flushes the filter element carrying the contaminates back out to the process stream, thus maximizing the filter element life. The low flow sample stream pulled into the analyzer is filtered to ranges of 200 micron to 0.5 micron (depending on the filtration efficiency required). Traditional T-type by-pass filters are detailed under Analyzer Filters.

The Fast Loop filters use axial velocity to flush heavy contaminates downstream while passing the sample through the element wall with low flow radial velocity. The annular cavity is filled and the sample passes into the sample line. Our 127IL-3 has an offset sample port for even more sweeping action and is available with (standard) 1/4” or 1/2” ports.

The annular cavity has very low volume to minimize lag time and keep the sample clean. For best results, a minimum of a 4 to 1 flow rate should be maintained for continuous flushing.

Features & Applications:

- 316L Stainless Steel Or PTFE Construction

- Compact Design For Fast Response Time

- Choose From Six Housing Sizes

- Sample Process Conditioning

- Cooling Water Analysis

| TECHNICAL INFORMATION | |||

| Housing Model | 116IL-3 | 126IL-3 | 127IL-3* |

| Inline Port Size (NPT) | 1/4” | 1/4” | 1/4” |

| Sample Port Size (NPT) | 1/4” | 1/4” | 1/4” |

| Maximum Pressure (psig) | 5000 | 5000 | 5000 |

| Internal Volume (cc) | 20 | 28 | 58 |

| Annular Volume (cc) | 11 | 15 | 30 |

| Maximum Temp. -Buna-N (250ºF) | BN126IL-3 | BN126IL-3 | BN127IL-3 |

| Maximum Temp. -EPDM (300ºF) | GE126IL-3 | GE126IL-3 | GE127IL-3 |

| Maximum Temp. -Viton (400ºF) Standard | GV126IL-3 | GV126IL-3 | GV127IL-3 |

| Maximum Temp. -Silicone (450ºF) | GS126IL-3 | GS126IL-3 | GS127IL-3 |

| Maximum Temp. -Kalrez (600ºF) | KZ126IL-3 | KZ126IL-3 | KZ127IL-3 |

| Estimated Weight of Housing (lbs) | 2.0 | 2.5 | 4.0 |

| Principle Dimensions: (inches) | |||

| Center Of Port To Inlet Port | 1.39 | 1.89 | 1.77 |

| Body Diameter | 1.97 | 1.97 | 1.85 |

| Overall Length | 2.79 | 3.78 | 6.69 |

| Element Removal Clearance | 1.97 | 2.95 | 5.70 |

| Filter Element Codes: (1) | |||

| Stainless Steel Element | SS-12-32-□ | SS-12-57-□ | SS-12-127-□ |

| PEL Element | PEL-12-32-□ | PEL-12-57-□ | PEL-12-127-□ |

| PTFE Element | PT-12-32-□ | PT-12-57-□ | PT-12-127-□ |

| Materials Of Construction: (2) | |||

| Body & Internals | 316LSS | 316LSS | 316LSS |

| O-Rings (Standard) | Viton | Viton | Viton |

| PTFE Housing Model Maximum Temp: 300°F Maximum Pressure: 100 PSIG | N/A | 126PIL-3 | 127PIL-3 |

Notes:

(1) Replace ‘□’ with micron required, e.g. SS-12-57-03T

(2) Material abbreviations, 316LSS = 316L Stainless Steel

(*) 127IL-3 standard with all 1/4” ports. 127IL-3-1/2”-1/4” has 1/2” inlet/outlet ports, and 1/4” sample

| TECHNICAL INFORMATION | |||

| Housing Model | 136IL-3 | 146IL-3 | 150IL-3-4015* |

| Inline Port Size (NPT) | 1/2” | 1/2” | 1” |

| Sample Port Size (NPT) | 1/4” | 1/4” | 1/2” |

| Maximum Pressure (psig) | 1500 | 1500 | 100 |

| Internal Volume (cc) | 94 | 240 | |

| Annular Volume (cc) | 32 | 90 | |

| Maximum Temp. -Buna-N (250ºF) | BN136IL-3 | BN136IL-3 | BN150IL-3 |

| Maximum Temp. -EPDM (300ºF) | GE136IL-3 | GE136IL-3 | GE150IL-3 |

| Maximum Temp. -Viton (400ºF) Standard | GV136IL-3 | GV136IL-3 | GV150IL-3 |

| Maximum Temp. -Silicone (450ºF) | GS136IL-3 | GS136IL-3 | GS150IL-3 |

| Maximum Temp. -Kalrez (600ºF) | KZ136IL-3 | KZ136IL-3 | KZ150IL-3 |

| Estimated Weight of Housing (lbs) | 4.0 | 7.5 | 9.0 |

| Principle Dimensions: (inches) | |||

| Center Of Port To Inlet Port | 2.24 | 4.56 | 5.55 |

| Body Diameter | 2.50 | 2.50 | 3.50 |

| Overall Length | 4.50 | 9.12 | 11.09 |

| Element Removal Clearance | 3.35 | 7.87 | 7.87 |

| Filter Element Codes: (1) | |||

| Stainless Steel Element | SS-25-64-□ | SS-25-178-□ | SS-51-230-□ |

| PEL Element | PEL-25-64-□ | PEL-25-178-□ | PEL-51-230-□ |

| PTFE Element | PT-25-64-□ | PT-25-178-□ | PT-51-230-□ |

| Materials Of Construction: (2) | |||

| Body & Internals | 316LSS | 316LSS | 316LSS |

| O-Rings (Standard) | Viton | Viton | Viton |

| PTFE Housing Model Maximum Temp: 300°F Maximum Pressure: 100 PSIG | 136PIL-3 | 146PIL-3 | N/A |

Notes:

(1) Replace ‘□’ with micron required, e.g. SS-25-178-03T

(2) Material abbreviations, 316LSS = 316L Stainless Steel

(*) 150IL-3 opens at both ends

Fast Loop Filter Design

The 116IL-3, 126IL-3, 127IL-3, 136IL-3 and 146IL-3 are machined from solid bar stock which eliminates welds and provides a 5000 and 1500 PSIG rating respectively. The 116IL-3 is designed for panels with a very small foot print and minimal contamination.

Our 150IL-3 is constructed of three components to reduce weight, and make element service easier; both end caps are threaded to the filter body. This design reduces the pressure rating to 100 PSIG, but significantly reduces housing mass. Please keep in mind, that we do make Fast Loop style filters in custom sizes and in other materials including PTFE, Monel, Hastelloy, and Inconel.

We also offer the model 137G-FL and 147G-FL which provide a Pyrex bowl to visually monitor the process. In these cases the traditional drain port is used as the inlet, and the traditional inlet is used as the fast loop outlet port. Please consult us for your specific needs. SS Pyrex Filter Housings

Why use a Fast Loop Filter?

The short answer is, in heavily contaminated sample process applications where a traditional T-Type filter blinds off too quickly because it “filters” the entire stream. This design also automatically cleans the inside of the filter element with a flushing motion. The Fast Loop filter only filters the sample line, thus reducing sample analyzer response times.

Maintaining the Filter Element

We recommend using our five layered stainless steel mesh elements which can be washed in place by back-flushing them, or removed and ultra-sonically cleaned, or in worst case scenarios once they are completely impeded with particulate they must be disposed of and a new element installed. The flushing action of the fast loop stream helps keep the element clean but in no way scrubs the element completely.

Stainless Steel elements consists of five layers of precision-woven 316L stainless steel mesh formed into cylinders and sintered together; the filter layer being supported, protected and pre-filtered by two inner and two outer layers. Five layers offer surface area and depth area for removing solids and dropping out liquids. UFS offers seven standard grades of filtration with a 98% efficiency in the following microns: 01, 03, 10, 25, 50, 100 and 200. Grade 25 (25 micron) is widely used to protect sample flows from visible particulate while grade –03 is recommended for the removal of pipe scale from steam. Non-standard micron sizes are typically sintered elements, such as the 005, (0.5 micron).

Stainless Steel elements consists of five layers of precision-woven 316L stainless steel mesh formed into cylinders and sintered together; the filter layer being supported, protected and pre-filtered by two inner and two outer layers. Five layers offer surface area and depth area for removing solids and dropping out liquids. UFS offers seven standard grades of filtration with a 98% efficiency in the following microns: 01, 03, 10, 25, 50, 100 and 200. Grade 25 (25 micron) is widely used to protect sample flows from visible particulate while grade –03 is recommended for the removal of pipe scale from steam. Non-standard micron sizes are typically sintered elements, such as the 005, (0.5 micron).

PTFE sintered elements are used where sample compatibility is of concern. Two grades of filtration are available with a 98% efficiency: 3 and 25 micron.

For best results use Five-Layer Mesh Stainless Steel elements or Sintered PTFE elements. We do not recommend using disposable microfiber elements with Fast Loop assemblies.

| SAMPLE STREAM WATER FLOW RATES IN GPH (LPM) AT 1.5 PSI DROP | ||||||||

| SS | PTFE | PEL | Housing Model Series | |||||

| Micron Size | Micron Size | Micron Size | 116IL-3 | 126IL-3 | 127IL-3 | 136IL-3 | 146IL-3 | 150IL-3 |

| 126PIL-3 | 127PIL-3 | 136PIL-3 | 146PIL-3 | |||||

| 110 Series | 120 Series | 130 Series | 140 Series | 150 Series | ||||

| 005 (0.5 M) | -- | -- | 1 (.06) | 2 (0.2) | 4 (0.25) | 5 (0.3) | 11 (0.7) | 34 (2.0) |

| 01 (1 M) | -- | -- | 3 (0.2) | 5 (0.3) | 10 (0.6) | 13 (0.82) | 32 (2.0) | 79 (5.0) |

| 03 (3 M) | 3 | -- | 6 (0.4) | 11 (0.7) | 20 (1.2) | 26 (1.6) | 61 (3.8) | 158 (9.9) |

| 10 (10 M) | -- | 10 | 16 (1.0) | 26 (1.6) | 45 (2.9) | 62 (3.9) | 111 (7.0) | 317 (20.0) |

| 25 (25 M) | 25 | 25 | 21 (1.3) | 27 (1.7) | 57 (3.6) | 84 (5.3) | 132 (8.3) | 343 (21.6) |

| 50 (50 M) | -- | 75 | 22 (1.4) | 29 (1.8) | 63 (4.0) | 90 (5.6) | 140 (8.8) | 360 (23.0) |

| 100 (100 M) | -- | -- | 23 (1.5) | 33 (2.1) | 65 (4.1) | 95 (5.9) | 158 (9.9) | 370 (23.3) |

| 200 (200 M) | -- | 250 | 29 (1.8) | 41 (2.6) | 81 (5.1) | 118 (7.4) | 185 (11.7) | 462 (29.0) |

Above flow rates are gallons per hour (liter per minute).

Note: Support cores should not be used with Fast Loop housings 126IL-3, 127IL-3, 136IL-3 and 146IL-3. They should only be used with traditional T-type housings.

Flow rates are generally proportional to pressure drop. If initial pressure drop of 3 psi can be tolerated, then the above flow rate can be doubled. Flow rates are generally inversely proportional to liquid viscosity.

For best results use Five-Layer Mesh Stainless Steel elements or Sintered PTFE elements. We do not recommend using disposable microfiber elements with Fast Loop assemblies.